Which Flexible PCB Board for led strip? What are its advantages and disadvantages?

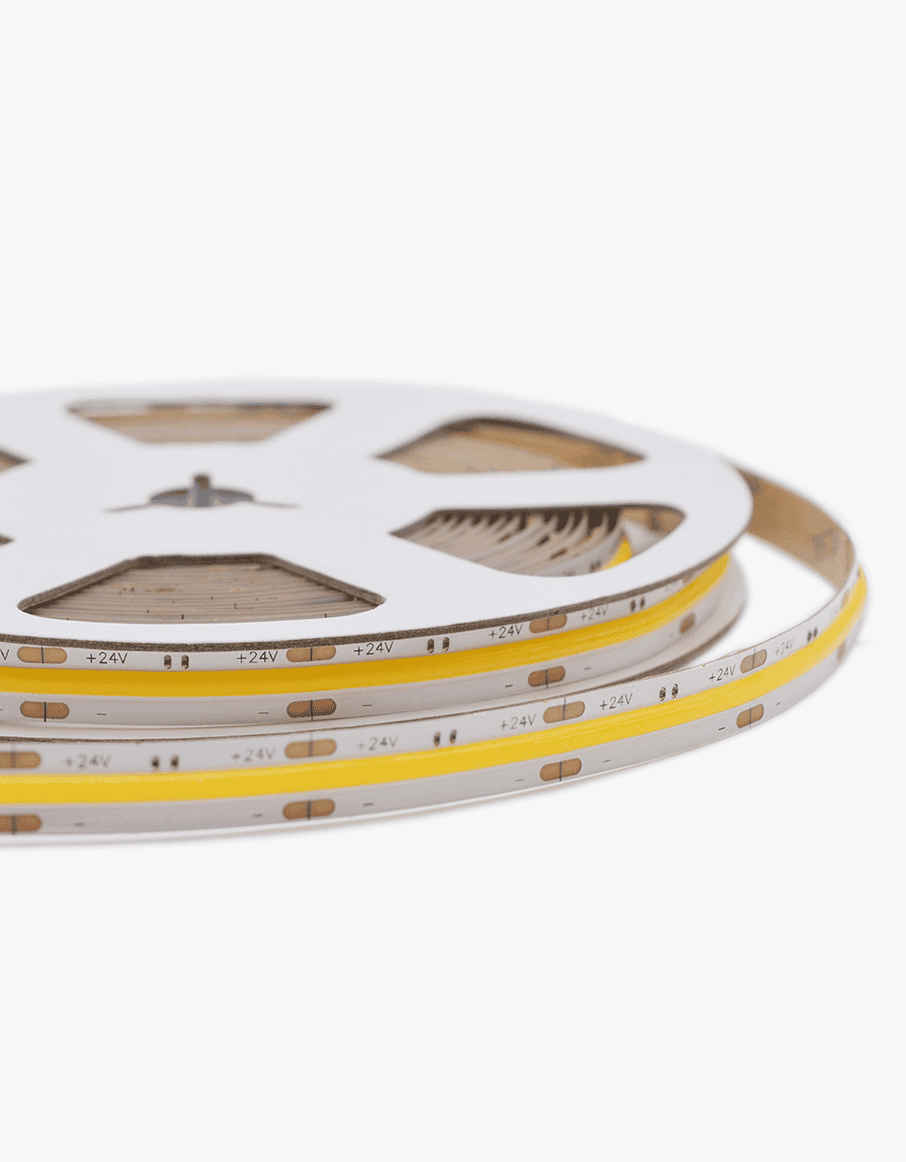

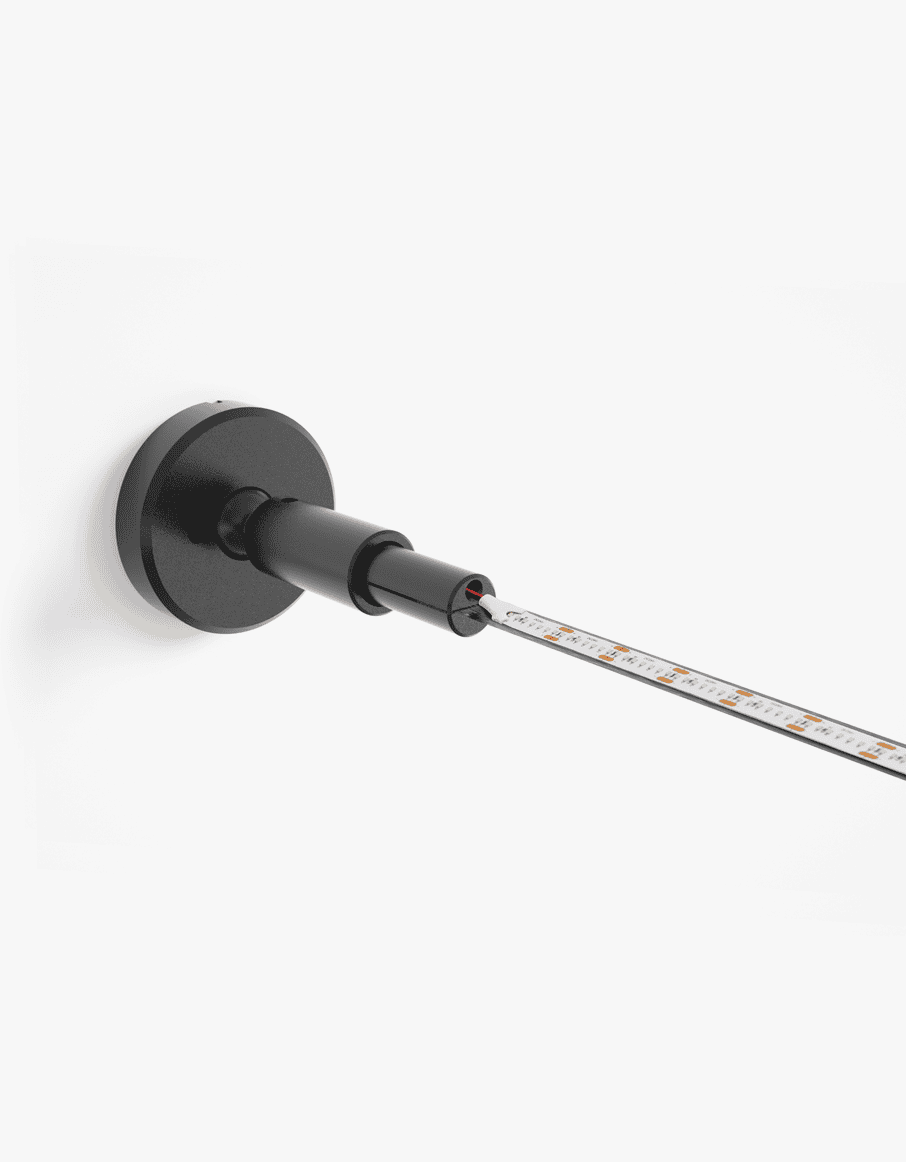

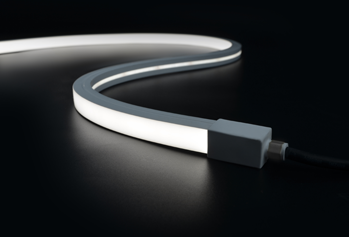

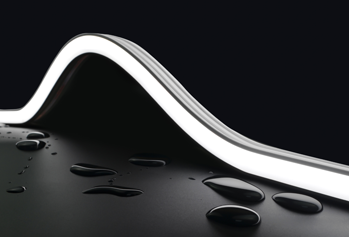

LED Strip, also known as the flexible LED stript, use flexible circuit boards, soft and dexterity, bending resistance, flexibility is very high, widely used in the production of linear lighting products such as led strip. The unique characteristics of flexible circuit board make it become a big demand in many occasions, but also promote the development of many fields.

Flexible circuit board's standard category:

1.Single Sided Board

Using single-side PI coated copper board in the completion of the circuit, and then covered with a layer of protective film, form a flexible circuit board only with a single conductor

2.Double Sided Board

Using double-side PI coated copper board in the completion of the double circuit, and then covered with a layer of protective film, form a flexible circuit board only with a double conductor

3.The substrate generates a single sided board

Use pure copper foil material in the circuit production, respectively covered with a layer of protective film on both sides, become a single layer of conductor, but has the conductor exposed circuit board on both sides of the circuit board

4.The substrate generates a double sided board

The use of two layers of single-sided PI copper plate material supplemented by a window in a specific position of the adhesive compression, the local area of the two-layer separation structure of the two-sided conductor circuit board in order to achieve high flexural performance circuit board in the layered area.

The flexible PCB board have four main type above.

Its advantages:

1. Can be free bending, winding, folding , can be arranged according to the space layout requirements.

2. Use FPC to reduce the size and weight of electronic products.

3.FPC also has good heat dissipation and weldability, as well as easy to assemble, the comprehensive cost is low.

Its disadvantages:

1. High initial cost

Because the flexible PCB boards are designed for special applications, the cost is higher for the circuit design, wiring and photographic backboard, unless there is a special need for flex PCB applications

2.It is difficult to change and repair flex PCB

Once the flexible PCB board is made, it must be changed from the base drawing or the preparation of the light drawing program if need to change, so it is not easy to change. Its surface is covered with a protective film, which must be removed before repair and restored after repair, which is relatively difficult work.

3.Size limitation

The flex PCB circuit board usually use intermittent process manufacturing in the case of not yet popular, so limited by the size of production equipment, can not be made very long, very wide.

4. Improper operation will easily damage